The yaw bearing of the wind turbine is installed at the connection between the tower and the cockpit, and the pitch bearing is installed at the connection between the root of each blade and the hub. Each wind turbine uses one set of yaw bearings and three sets of pitch bearings. The material of the yaw and pitch bearing rings is 42CrMo. The heat treatment adopts overall quenching and tempering treatment, and the raceway surface is quenched. The stress conditions of yaw and pitch bearings are complex, and they bear relatively large impacts and vibrations. Therefore, the bearings are required to withstand both impacts and large loads. The life span of the wind turbine main engine is required to be 20 years, and the cost of bearing installation is relatively high. Therefore, the life span of the yaw and pitch bearings is also required to be 20 years. The base hardness of the bearing ring is 240-280HB, which can withstand impact without plastic deformation. At the same time, the quenching hardness of the raceway surface reaches 55-62HRC, which can increase the contact fatigue life and ensure the use requirements of the bearing life.

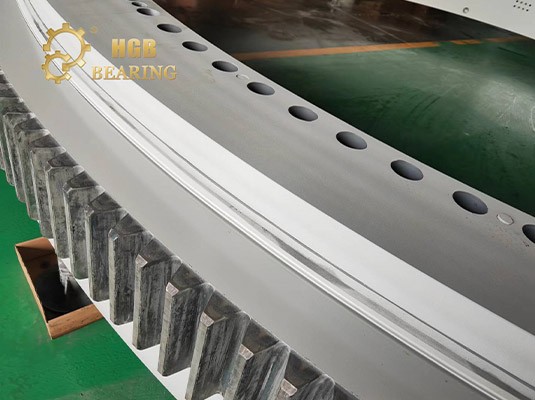

Slewing bearing for wind turbines is a large bearing, mainly used in pitch and yaw systems. It is loaded with complex loads and is very difficult to disassemble and maintain. Therefore, the design and manufacturing requirements of wind power slewing bearings are strict. Slewing bearings are the core components of wind turbines and are widely used in the pitch and yaw systems of wind turbines. The pitch bearings are used to connect the hub and blades, and the yaw bearings are used to connect the tower and the unit. Wind power slewing bearings are very difficult to maintain due to their large size and difficult installation location. Moreover, once the slewing bearing fails, it will directly affect the performance of the wind turbine and even cause shutdown. Therefore, wind power slewing bearings are required to have high reliability and long service life, at least reaching the 20-year service life of the wind turbine.

Luoyang Heng Guan Bearing Technology Co., Ltd is an entity manufacturer of slewing bearings and customized non-standard machining parts. Our company integrates professional design, research and development, manufacturing, sales and service. Relying on the strong manufacturing capacity and research and development capacity, we can provide customers with one-to-one customized services and solutions.

If you have any inqury or questions for our products, please feel to contact us.

Submit Request

PDF Request

Simply fill out the form below and the catalog will be available for download!