News

Gear transmission is a mechanical system that uses the meshing of two or more gear teeth to transmit power and motion. This method is known for its high efficiency, reliability, and precise speed ratio, making it widely used in various types of machinery.

Transmission Ratio Formula:i=n2n1=z1z2

Basic Principles:

| Type | Characteristics | Main Applications |

|---|---|---|

| Spur Gears | Simple structure, easy to manufacture | General machinery, clocks |

| Helical Gears | Smooth operation, low noise | Vehicle transmissions, reducers |

| Bevel Gears | Can change the direction of transmission | Automotive differentials, machine tools |

| Worm Gears | High transmission ratio, self-locking capability | Cranes, elevators |

Advantages:

Disadvantages:

Gear transmission achieves efficient and precise power and motion transfer through the accurate meshing of teeth. From simple watches to complex industrial machinery, these basic principles support the operation of the modern mechanical world. Understanding the fundamentals of gear transmission helps us comprehend how many mechanical devices around us work.

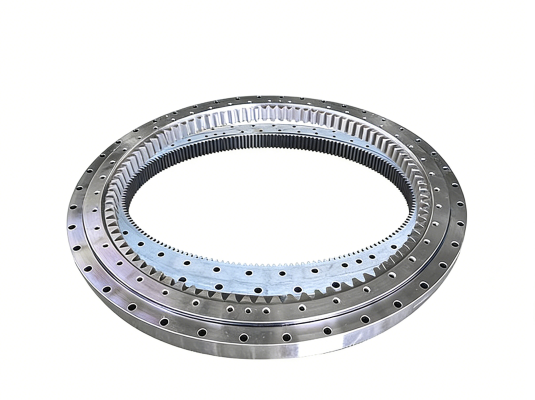

Luoyang Hengchang Heavy Machinery Co., Ltd. is an entity manufacturer of slewing bearings and customized non-standard machining parts. Our company integrates professional design, research and development, manufacturing, sales and service. Relying on the strong manufacturing capacity and research and development capacity, we can provide customers with one-to-one customized services and solutions.

If you have any inqury or questions for our products, please feel to contact us.

Industry News / Mar 19, 2025

Precautions and tips for installing the new environmentally friendly rotary kiln large gear ring

Industry News / Feb 26, 2025

Considerations for slewing bearing selection

Industry News / Feb 21, 2025

Slewing bearing seal belt removal skills

Submit Request

PDF Request

Simply fill out the form below and the catalog will be available for download!