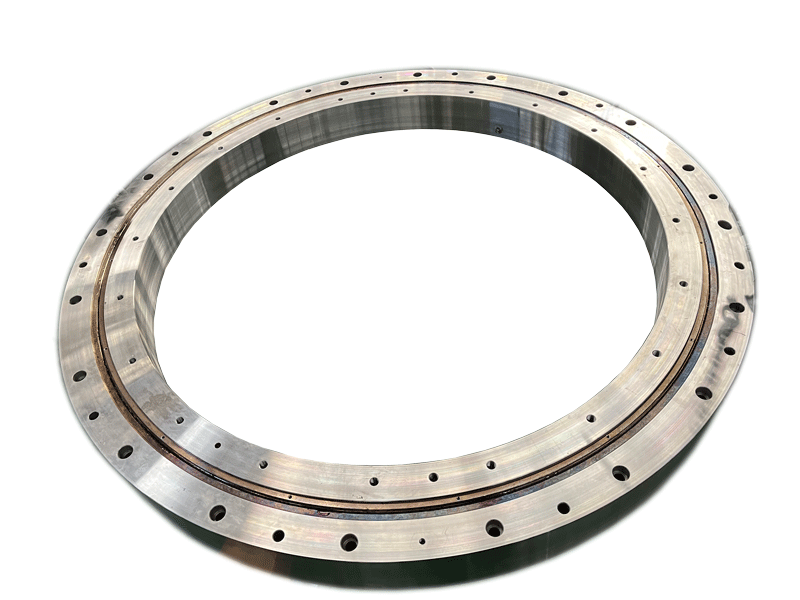

Slewing bearing of the ship unloader usually adopts a three-row roller structure with external gear and a diameter of about 4 meters.

The slewing structure of a ship unloader consists of two parts: the slewing support device and the slewing drive device. It uses a slewing bearing to transmit vertical forces, horizontal forces, and overturning moments, enabling the ship unloader to rotate. Its performance indicators directly determine the usability and safety performance of the loading and unloading machinery. When a breakdown occurs, it is usually necessary to lift the upper structure, weighing thousands of tons, to a certain height to repair or replace the large slewing bearing. This results in long repair times, high costs, significant indirect losses due to downtime, and even the potential for safety accidents.

Slewing bearings are a new type of mechanical component that has gradually developed alongside the progress of the world's machinery industry over the past 50 years. Initially used in tower cranes, mobile cranes, and excavators, their applications have gradually expanded to include transportation machinery, metallurgical machinery, food processing machinery, military equipment, tanks, anti-aircraft guns, radar, rocket launchers, medical machinery, ladders, windmills, robots, and rotating amusement rides.

Luoyang Hengchang Heavy Machinery Co., Ltd. is an entity manufacturer of slewing bearings and customized non-standard machining parts. Our company integrates professional design, research and development, manufacturing, sales and service. Relying on the strong manufacturing capacity and research and development capacity, we can provide customers with one-to-one customized services and solutions.

If you have any inqury or questions for our products, please feel to contact us.

Submit Request

PDF Request

Simply fill out the form below and the catalog will be available for download!